Mastering Tool Tracking: Boosting Efficiency and Protecting Investments in Construction

Tools are Expensive:

Are You Keeping Track of Them?

Have you ever experienced that sinking feeling when you realize a valuable tool has gone missing? You search high and low, turning your site, truck, or warehouse upside down, only to come up empty-handed. It’s a frustrating and costly situation that many construction professionals have faced. The truth is, tools are not only essential for the success of your projects, but they also represent a significant financial investment. How are you keeping track of that investment?

Companies like yours invest substantial amounts of money in acquiring the tools necessary to tackle diverse projects. From power tools to specialized equipment, the costs quickly add up. However, the value of these tools extends far beyond their price tags. They are vital assets that directly contribute to the success of your projects and, ultimately, your bottom line.

Yet, we often find that many construction companies fail to implement a tool tracking system, leading to a myriad of issues. Misplaced or lost tools result in delays, setbacks, and the unnecessary repurchasing of items that may be under utilized. Furthermore, the underutilization of tools due to lack of visibility can hinder productivity and prevent you from optimizing your resources effectively.

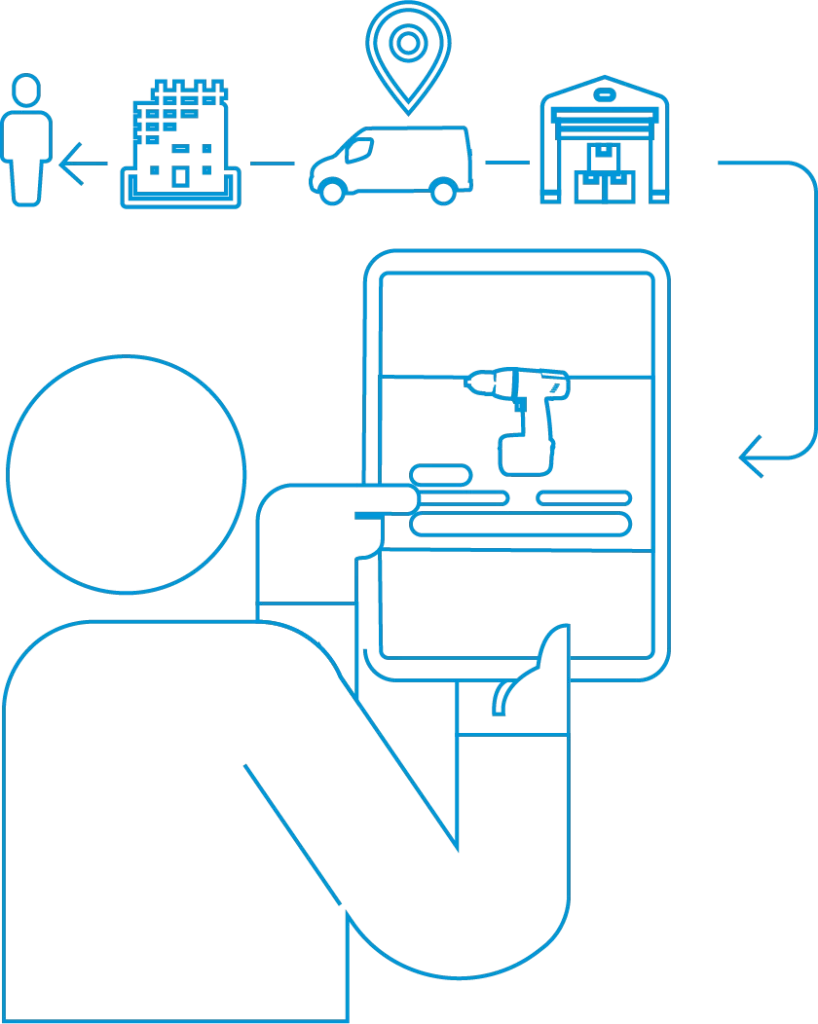

It’s time to shift the narrative and recognize the importance of tracking tools. By implementing an effective tool management system, you can gain real-time visibility into your inventory, ensuring that your tools are always available when you need them. Not only does this streamline your operations and improve productivity, but it also eliminates unnecessary expenses and maximizes your return on investment.

In the following sections, we will explore the hidden costs of poor tool tracking, the benefits of maximizing tool utilization, and how streamlining your inventory management can lead to significant cost savings. We will also delve into the importance of preventing unauthorized use and loss, as well as the potential return on investment that comes with effective tool tracking practices.

So, are you ready to take control of your tool inventory? Let’s dive into the world of efficient tool tracking and discover how it can transform your construction business for the better.

The Hidden Cost of Poor Tool Tracking

Misplaced tools, lost equipment, and inadequate tool tracking may seem like minor inconveniences at first glance. However, the consequences of poor tool tracking can have far-reaching implications for your construction company. Let’s explore the hidden costs associated with neglecting to track your tools effectively.

Delays and Project Setbacks:

When a tool is misplaced or goes missing, it can bring your construction projects to a screeching halt. Workers may spend valuable time searching for the tool, causing delays and disrupting the project timeline. This can lead to missed deadlines, dissatisfied clients, and potentially costly penalties. With poor tool tracking, you risk compromising the smooth flow of your operations and jeopardizing project success.

Unnecessary Repurchasing:

Without accurate records of your tool inventory, it’s easy to fall into the trap of repurchasing tools that are already within your possession. This redundancy not only wastes money but also creates a surplus of unnecessary tools, tying up valuable capital that could be invested elsewhere. By properly tracking your tools, you can avoid unnecessary repurchasing and make more informed decisions regarding tool acquisitions.

Reduced Productivity:

Inefficient tool tracking practices can hamper productivity on sites. When workers don’t know the location of specific tools or have to spend time searching for them, valuable working hours are wasted. This leads to decreased productivity, decreased output, and increased labor costs. By implementing an effective tool tracking system, you can ensure that your workers have easy access to the tools they need, minimizing downtime and maximizing efficiency.

Increased Labor Expenses:

Poor tool tracking can indirectly contribute to increased labor expenses. When tools are not readily available, workers may resort to workarounds or makeshift solutions, which can be time-consuming and potentially unsafe. Additionally, without proper tool tracking, it becomes challenging to allocate tools efficiently across different projects or teams. This may result in unnecessary duplication of efforts and increased labor costs. By accurately tracking tools, you can optimize resource allocation and reduce labor expenses.

Inefficient Resource Management:

Your tool inventory represents a significant investment, but without proper tracking, you may be unaware of the actual value and condition of your assets. Tools that are not properly maintained or are overlooked in the inventory may deteriorate over time, reducing their lifespan and requiring costly repairs or replacements. Effective tool tracking allows you to monitor the condition of your tools, schedule maintenance when needed, and optimize their lifespan, thus avoiding unnecessary expenses.

Download the rest of our guide, plus get more information about tool tracking and ShareMyToolbox.